Home | Repair

At Radio Design, our aim goes beyond simply crafting top-of-the-range telecommunications equipment. We are devoted to ensuring its longevity and peak performance, embracing sustainability in our approach. Our Repair division provides world-class repair solutions, reducing electronic waste and contributing to a greener future.

Inspired by our vision of delivering exceptional and sustainable repair services, we’ve established multiple repair centres across the globe. Each of these centres of excellence is equipped to manage high volumes of equipment repair, specifically tailored to support its local market. We’ve streamlined product transfers between centres, offering truly international service and swift, global repair capabilities.

Our highly skilled team forms the backbone of our processes. Staff are fully trained in their areas of expertise and are dedicated to implementing efficient working practices. Along with the extensive RF experience within the company, we can devise effective repair strategies customised to specific needs.

Our dedicated management, sales, engineering, and production resources ensure a high level of flexibility and support, allowing us to offer bespoke repair solutions. Continuous improvement and future planning are at the core of our ethos.

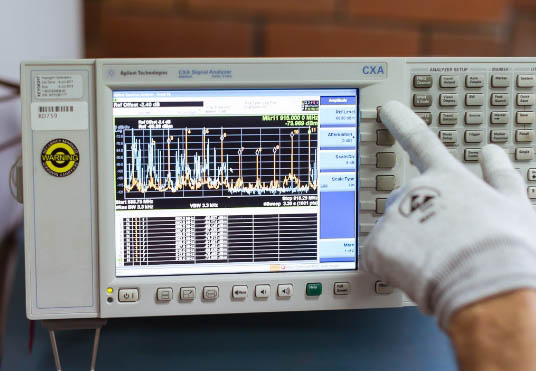

To guarantee quality, we employ robust methods and detailed testing designed specifically for each product type under repair. We have the capacity to create bespoke test interfaces and provide optimised test software. Our engineering group supports a continuous improvement programme to refine our repair processes and methodologies.

From it’s origins in the RF product domain, Radio Design’s engineers have a breadth of experience from many years in the industry. This knowledge and expertise is applied to all aspects of the services, and all products that are repaired.

Leveraging product design expertise and our dedicated engineering team, Radio Design offers comprehensive third-party engineering solutions. This includes everything from simple filters to complex transceivers. Particularly for OEM products lacking support or hard-to-obtain data, we provide cost-effective repair solutions.

A low BER/Scrap rate means less expenditure on replacement product. Radio Design employs a manufacturing based NPI process for launching a product into volume repair. This enables reduced scrap rates (or Beyond Economical Repair). Ongoing engineering activity is undertaken to reduce BER rates further.

OEM current and legacy support is provided by Radio Design through close partnerships to support OEM equipment – both current and legacy units.

Radio Design efficiently performs multifaceted repairs, thanks to our meticulous technicians and engineers. We ensure comprehensive repairs, even down to component level, which helps save products that would otherwise be scrapped.

Where a product is deemed to need regional repair and screening services, Radio Design can provide a low cost method to only send genuine failures for repair.

A unique capability to support medium to high volume products, supporting OEM, third party & multi-vendor repairs

Radio Design Ltd Registered Office – 37 Albyn Place, Aberdeen, AB10 1YN Registered In Scotland – No. 328828

Fill out the form below and we will contact you as soon as possible

Fill out the form below and we will contact you as soon as possible